Pellets

Pellets are a form of solid biofuels; it is different with briquettes in terms of material, improved calorific value and costing. The underlying principle remains similar with both (briquettes and pellets) being made from mechanical densification of the cellulosic waste material such as agriculture residue, biomass or saw dust etc. BJPL manufactures and supplies the following pellets:

Commercial Grade Pellets

These pellets are suitable for commercial pellets burners and stoves which are used as cost effective replacements of LPG, diesel based burners. Commercial grade pellets are made from refined sawdust and wood chips. The careful processing of woodchips and sawdust with state of the art pellet line result into very fine quality pellets with low ash upto 5% ash and GCV above 4200. Gross Calorific Value (Kcal/kg) 4200-4400, Ash Content Less than 5%

Industrial Grade Pellets

Industrial pellets usage is picking up pace due to incremental automation in boiler firing in India. These pellets are made from agriculture waste such as soybean husk, cotton stalk etc. Industrial pellets are approximately 20% more efficient than briquettes due to very low moisture, ash percentage and higher bulk density compared to briquettes.

Current Scenario for Fossil Fuel Usage

Pellets to replace LPG or Diesel can get 50% saivings to a small business – which is large enough reason to shift ! – 1 Ltr of diesel (Rs80/ ltr) can be replaces with 2.5kg of Pellets (Rs33)- 60% savings – 1 Kg of LPG (Rs70/ kg) can be repalced by 3kg Pellets (Rs39) – 50% savings

Why it’s economical for big industries to purchase Pellets instead of coal

Example : Cost of electricity is estimated at €0.12 per kWh for BPBP projects as compared to €0.10 per kWh for imported coal based power plants. For states with the lower tariff for biomass power, the break-even price of carbon for BPBP projects is estimated at €18 per tonne. Additionally, BPBP projects will generate employment of more than 5 million person-months in the construction of biomass power plants and over 200,000 full-time employments in the operation of BPBP plants and in the production of biomass pellets.

How Do We Source Our Products?

Pellets: (diameter- 6 to 12 mm); Raw material – Wood waste: Wood Chips, Saw dust – Agriculture waste – Soybean husk, Cotton stalk, Mustard stalk, Chana husk, Ground nut shells, Coffee husk, USAGE: Commercial burners, Small Stoves and Power plants ** to replace: Diesel, LPG, Furnace Oil and Coal (in power plants)

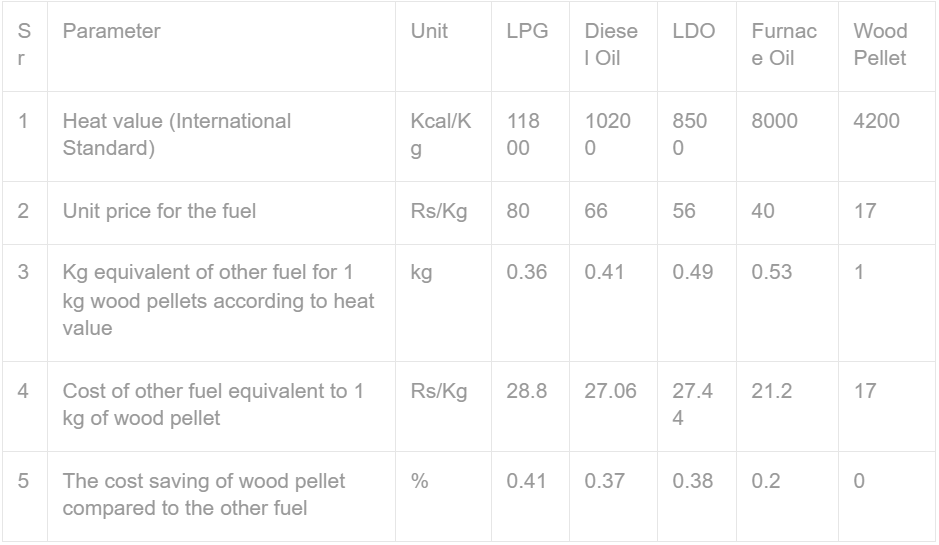

Energy saving comparison chart: Pellets are significantly cost effective than other fuels.

- Using Pellets to replace LPG or Diesel can get 50% savings to a small business which is large enough reason to shift !

- 1 Ltr of diesel (Rs80/ ltr) can be replaces with 2.5kg of Pellets (Rs33)- 60% savings

- 1 Kg of LPG (Rs70/ kg) can be repalced by 3kg Pellets (Rs39)

- 50% savings Most small businesses (SME and proprietor shops) with time are part of residential areas and face stricter environmental or pollution norms

- Thus have to shift from coal or raw wood to Pellets Furnace Oil volatility and price levels makes briquettes viable a lot.

- 3 Kg Biomass Briquettes (Rs20) replace 1 Ltr Furnace oil (Rs40) – 50% Savings