There is very little awareness around the fact that Biofuel Pellets are completely capable of replacing LPG and Diesel. And the application and usage of Pellets range from a small stove in a canteen to sophisticated heating burners in an injection moulding or a plastic moulding factory. Here are top 4 reasons why there’s sudden surge in usage of Pellets in India.

1. Pellets Are Highly Cost Effective As Compared To LPG & Diesel

Pellets are also highly cost effective in comparison to Diesel and LPG. One kg of LPG will roughly cost you around Rs.70/-. And to replace the one kg of LPG or one kg of diesel, you need two to two and a half kilograms of Pellets, which will cost you anywhere between Rs.40/- to Rs.50/- which much more cost effective. Because of this reason, the usage of Pellets is increasing in India. However, a large population of people are still not aware about this great cost effective benefit.

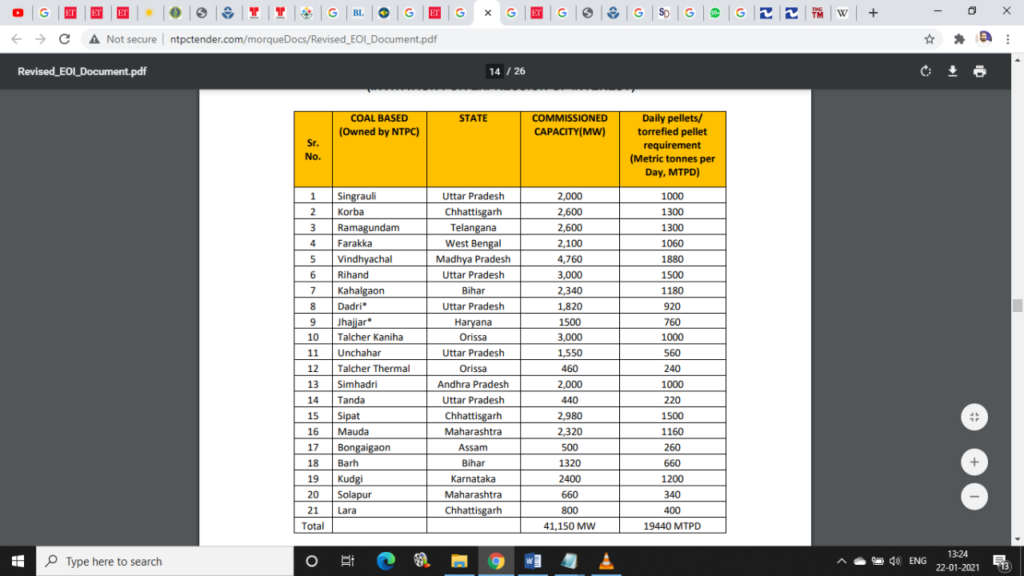

2. The Indian Government is Encouraging the Usage of Environment-Friendly Fuels

The Indian Government in many states of India is encouraging the usage of environment friendly fuels which have less CO2 emission. Solid Biofuels fall under the category of less CO2 emitting fuels. Pellets, which are an extension of Biomass emit very little CO2.

Currently, the Indian snack businesses that are present across many states in India, make snacks in huge clusters. They have been operating in the Indian snacks business since about thirty to fifty years. The main source of fuel to cook the snacks was always coal, raw wood, saw dust, diesel or LPG.

Earlier, they were located on the outskirts of the cities. Hence, though the CO2 emission was high due to these fuels, it didn’t directly and quickly impact the population living in the cities. But recently, they have shifted to main areas inside the city. And hence, now the CO2 emission has become dangerous for the people living in the locality.

So as the resolution, the Indian government has actively pushed the agenda to use a less smoke creating and cleaner source of fuel. And Biomass Pellets completely qualify this condition.

3. Pellets Allow the Usage of Automation

Although raw fuel sources like coal, raw wood, and saw dust are much cheaper, Indian snack businesses are slowly shifting towards the usage of Pellets. And a reason for this shift is because Pellets allow the usage of automation for effective functioning.

Because of automation, the process parameters can be controlled perfectly to a Tee. For example, a manufacturer is required to have 180 degrees of temperature to roast certain snacks, a Pellet burner assures him a level of temperature, close to 180 degrees with very little hassle.

So there are Pellet burners which allow you to set the temperature, monitor the temperature and you can control the temperature to the required centigrade, as per the type of snack. These aspects of controlling and monitoring are not possible in raw fuels.

In case of raw fuels, many a times they are heterogeneous, there moisture levels are not known, their ash content is not known and their exact type is not known. This is also one strong reason why many food manufacturing businesses are shifting to Pellets.

4. From Canteens to Plastic Moulding There’s a Sudden Increase in Usage of Pellets

To understand this sudden surge of usage of Pellets, let’s consider a popular example. The increase in usage of 4G internet isn’t there because it is cheap. It is because the handsets that allow 4G internet to function have become a lot cheaper than they were before. Hence, people can afford buying the handsets and thereby, there is a steep surge in the usage of 4G internet.

Likewise, five years ago in Pellets, there was no improved Burner eco-system or hardware. The Pellet Burner’s hardware was not even sophisticated enough to be used by the manufacturers in a suitable format.

Today, the cost of these Pellet burners have gone down and the efficiency and sophistication have improved tremendously. And this is another strong reason that is driving the usage of Pellets across industries. Be it a small diary, a small snack manufacturer, a canteen or a large injection or plastic moulding manufacturing plant, Pellets have become highly popular.

In a nutshell, the cost effectiveness of Pellets and their burners, the improved efficiency of the burners and the advanced automation attached to them, are factors leading to a surge in usage of Pellets across the country.